External Engine Cleaning and Disassembly of Core Components (I)

Steam Cleaning of Engine Exterior

Before steam cleaning, all electrical parts must be removed, such as the generator and its adjusting rod, starter motor and all electrical control devices used. When disassembling, tags should be hung on the wires to facilitate identification during subsequent installation, and all orifices should be sealed with moisture-proof tape to prevent water vapor from entering the interior and damaging the parts. Steam cleaning can effectively remove oil, dust and other impurities from the engine exterior, which not only saves the time of subsequent actual maintenance work, but also makes the inspection work faster and more accurate due to the clean surface.

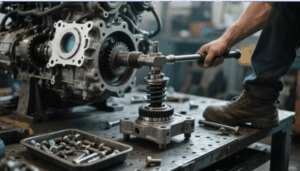

Turbocharger Disassembly

- Remove the oil inlet pipe and oil drain pipe. If the Klincher type nut is stuck or frozen, a chisel can be placed between the two corners of the hexagon nut and tapped with a hammer for disassembly. If a heat shield or heat plate is installed, it should be removed before disassembling the turbocharger.

2.Remove the hose clamp connecting the turbocharger and the air crossover pipe.

3.Remove the air crossover pipe between the turbocharger and the intake manifold to complete the disassembly of the turbocharger.

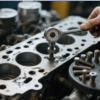

Water Pump Disassembly

- Close the valve above the cooling water filter, remove and discard the filter.

- Remove the water pipe assembly between the water pump and the cooler shell.

3.Remove the bypass pipe assembly between the water pump and the thermostat housing.

4.Remove the water pump bracket. When removing the water pump, the pump body should be kept parallel to the engine or withdrawn backward all the time to get out of the way of the drive shaft and studs and avoid damaging related components.

Related posts

Disassembly of Flywheel Housing and Oil Seal Disassembly of Connecting Rod-Piston Assembly To facilitate the removal of the piston pin, Rotate the engine so that... Continue reading

Disassembly of Oil Pan and Connecting Box Disassembly of Gear Chamber Steel Plate Disassembly of Flywheel Continue reading

Camshaft Disassembly Turning Device Disassembly Oil Pump Disassembly Continue reading

Water Pump Transmission Bracket Disassembly After removing the screws and stud nuts, remove the transmission bracket from the gear chamber with a soft hammer at... Continue reading

Cylinder Head Disassembly The cylinder head is assembled with the cylinder block using positioning pins. Remove the screws, lift the cylinder head upward from the... Continue reading

Add comment