Preparation Before Engine Disassembly

Before disassembling the KT(A)-1150 series Cummins diesel engine, various maintenance tools need to be prepared. The tools are divided into three categories: main maintenance tools, recommended maintenance tools and standard tools (locally available).

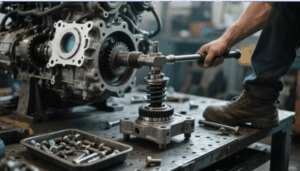

- Main Maintenance Tools: Including 3375016 camshaft gear puller, ST-1286 (2) engine lifting lugs, ST-1258 lifting fixture, 3375193 engine overhaul stand, ST-1307 engine stand support, ST-1313 camshaft guide rod, etc. These tools are essential for completing the core disassembly operations of the engine and are indispensable.

- Recommended Maintenance Tools: Such as ST-647 pulley puller, 3376000 fuel injector removal tool, ST-1116 main bearing cap puller, etc. Using these tools can make the disassembly process more convenient and efficient, and reduce the risk of component damage.

- Standard Tools: Including electric or chain hoists, steam cleaners, cleaning tanks, flushing tanks, power wrenches, glass bead blasting cleaners, etc., which are mainly used for auxiliary work such as cleaning after engine disassembly.

At the same time, before disassembly, a comprehensive inspection of the overall condition of the engine should be conducted, and the conditions before and during disassembly should be recorded. Each component should be inspected, and identification marks should be added to wires, components, bearing shell positions and other parts. Components should be removed from the cylinder block in a convenient order, and marks should be made on the removed components to identify their assembly positions. Components (except electrical parts) should be placed on a trolley for cleaning. Hoses, O-rings, gaskets and lock washers should be discarded. In addition, when removing screws from parts such as the oil cooler shell, oil pan connecting plate, front gear chamber cover and connecting plate, attention should be paid to their lengths to ensure correct thread fit during assembly.

Add comment