Disassembly of Engine Water Pump Transmission Bracket, Damper and Gear Chamber Cover

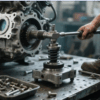

Water Pump Transmission Bracket Disassembly

After removing the screws and stud nuts, remove the transmission bracket from the gear chamber with a soft hammer at the front end of the shaft. Using a soft hammer can reduce the impact damage to the bracket and gear chamber.

Damper Disassembly

- The damper and crankshaft flange can be disassembled separately, or the screws that fix the flange to the crankshaft can be directly removed to disassemble them together.

- During disassembly, the flange can be gently pried and tapped, but the damper must not be pried or tapped. If the outer shell has dents, the damper will fail, affecting the damping effect of the engine.

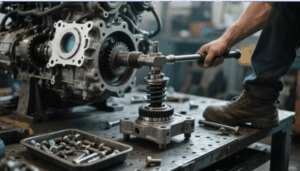

Gear Chamber Cover Disassembly

- Remove the gear chamber cover screws.

- Use an appropriate puller to remove the main positioning pin.

- Remove the gear chamber cover. During disassembly, attention should be paid to protecting the sealing surface of the gear chamber cover to avoid deformation affecting subsequent sealing.

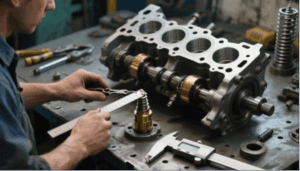

Idler Gear Disassembly

- Remove the idler gear retainer ring and outer thrust bearing.

- Remove the idler gear.

- Remove the inner thrust bearing. Disassemble in sequence to avoid part confusion.

Add comment